Flame Retardant ABS

-

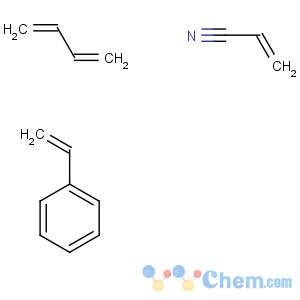

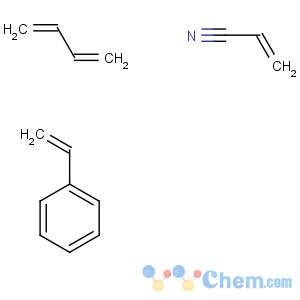

Molecular Structure

Detailed Description

- Product: New Type Flame Retardant ABS (Environment-Friendly)/MH-7800Z

- Characteristics:

This product is with proper formula, scientific technology and excellent property. At the same time, it can reach environment-friendly requirement. It can also meet the decree requirement of ROHS (by EU) and WEEE (by UK).

It does not contain any of the forbidden 73 ingredients by REACH. Compared to normal flame retardant ABS, the tensile property, bending property, articulated performance, chemical corrosion resistance, etc have been improved a lot. The high cost-effective performance cannot be matched by other flame retardant resins.

- Advantage:

1. Low density. Just equals to the density of the normal flame retardant ABS.

2. Good liquidity. The MFI exceeds normal flame retardant ABS.

3. High impact strength and good toughness.

4. Good fire-resistant property. 0.9mm can reach 5VA.

5. Good weather fastness. Especially suitable for outdoor products.

6. Low price. High cost-effective performance.

- Suggestions:

1. Drying temperature is 80℃/2 hours.

2. To guarantee the appearance and shape of the product, use extrusion of low pressure and low speed primarily.

3. Control the injection temperature between 165℃—175℃. It cannot exceed 180℃

- Usage:

When there is no special heat-resistant requirement, it is widely used in the fields of construction, electronics, electric appliance, automobile, medical device, etc.

In normal injection method, it can be used to produce the shells of computer, telephone, TV, etc and other impact-resistant plastic components.

jtchemical@hotmail.com

jtchemical@hotmail.com